Improved Prosthetic Functionality Through Advanced Hydraulic Design

DOI:

https://doi.org/10.57922/mec.67Abstract

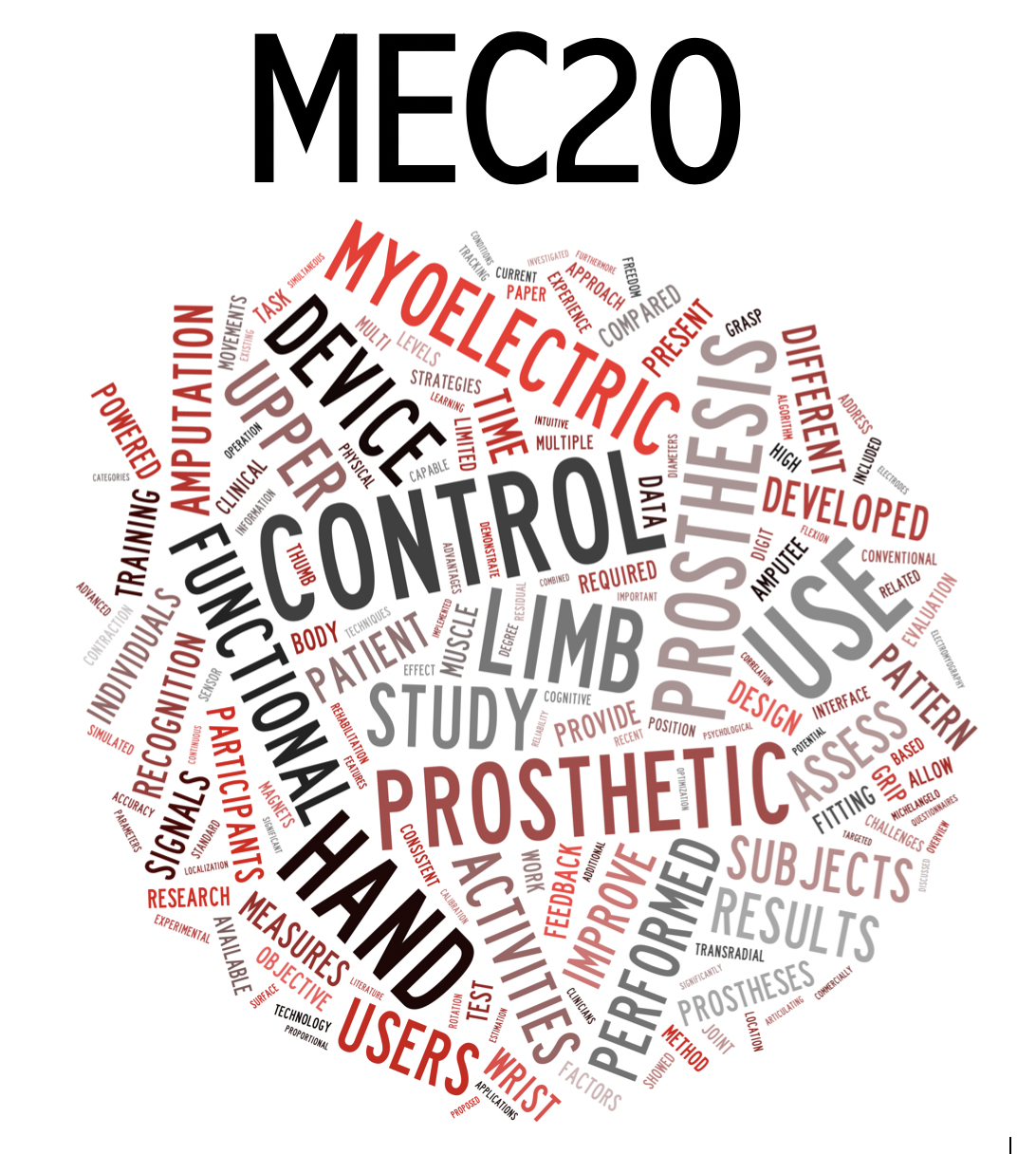

Hy5 met its research objective of designing a hand prosthesis to fill the gap between standard myoelectric grippers and premium, bionic-like hand prostheses. Our approach applied state-of-the-art hydraulic actuator technology with functionality embedded in advanced 3D printing of titanium and plastics. As a result, the opening and closing of the hand is myo-electrically controlled and compatible with industry standards while the hydraulics enable an adaptive and independent pressure build-up on the fingers as they grasp an object. This design mimicking realistic hand gripping without requiring one motor per finger as in bionic-like prosthesis.

Testing concluded that the MyHand prosthetic hand manages all grips (pinch, power, fist, tripod and point) as intended and works as a substitute for a missing hand. Users also responded very favourably to the innovative emergency release button, an added safety feature. The users were attracted by the simplicity and sturdiness of Hy5, which promises a reliable product with low life-cycle cost.